The Tajima TMBR2-SC1501 is high-end a single-head type embroidery machine allows you to add a wide variety of embroidery to finished products, and the DCP provides a precise and beautiful finish, regardless of the material. Suitable for name and emblem embroidery on uniforms, hats, socks, bags, etc. and for embroidery processing in stores.

NEEDLES 15

BORDER FRAME 360 x 500mm (14.1 x 19.6in)

WIDE CAP FRAME 75 X 360mm (2.9 x 14.1in)

SEMI WIDE CAP FRAME 83 x 180mm (3.2 x 7in)

TUBULAR FRAME 335 x 453mm (13.1 x 17.8in)

POCKET FRAME 1: 45 x 80 mm (1.7 x 3.1in)

POCKET FRAME 2: 80 x 55mm (3.1. x 2.1in)

OVERALL WIDTH 1205mm (47.4in)

DEPTH 770mm (30.3in)

HEIGHT 977mm (38.5in)

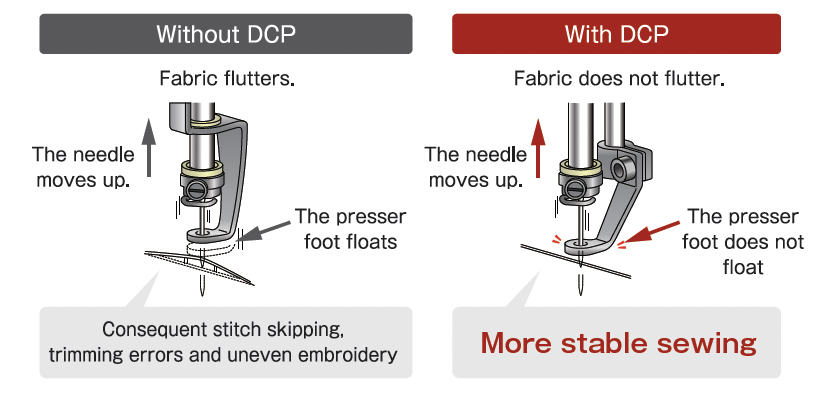

The Digitally Controlled Presser foot (DCP) measures the thickness of the fabric in 0.05 seconds per stitch and presses the fabric with optimal pressing force. Therefore, it instantly adapts to both thick and thin fabrics. Quilted fabrics are sewn with the padding pressed down firmly, while 3D embroidery using urethane is sewn three-dimensionally without pressing down excessively.

Equipped With One Of The Industry’s Largest Touch Screens!

The large 12.1-inch operation panel, one of the largest in the industry, features convenient icons and allows you to switch the language used for operating the machine.

STABLE FINISH FOR BOTH THIN AND THICK MATERIALS

It firmly holds fabrics from sheer to knit materials so that they do not flutter regardless of the item.

Embroidery is always applied with consistent quality to items of varying thickness and stiffness, such as T-shirts, hats, socks, bags, etc.

MINIMISE QUALITY DEFECTS

The DCP reduces fabric fluttering, resulting in fewer press marks and thread trimming errors, and thus fewer defective pieces. Manual adjustment for delicate fabrics such as velvet and enameled material reduces the risk of fabric press marks.

LARGE EMBROIDERY FIELD

With an embroidery field of 360 mm (14.4inches) (D) x 500 mm (20 inches) (W), it is ideal for large embroidery designs such as large bags and the backs of T-shirts, sweatshirts, etc.

FAST AND CLEAN CAP EMBROIDERY

Large-diameter shaft makes it easy for anyone to install the cap frame. Three-point locking between the drive ring and cap frame provides more stable fixation, less needle breakage and pattern misalignment, and operation at a maximum speed of 1,000 rpm.

LONG SLIM CYLINDER BEDS FOR SMALL GOODS

The smaller diameter of the cylinder bed and the smaller bobbin cover allows for easy embroidery on tubular finished products such as sleeves and pockets.

USER FRIENDLY DESIGN

In addition to i-TM and DCP, the machine offers a wide variety of operator-friendly functions and options. This reduces operator workload while ensuring high quality embroidery production and smooth machine operation.

NEW AUTO THREAD TRIMMING DEVICE

Eliminating the picker makes exchanging bobbins easier. It also provides more stable trimming and a 40% improvement over conventional machines in shortening thread tails on the reverse side of the fabric.

DESIGN POSITION ADJUSTMENT FUNCTION (CORRECTS FRAMING MISALIGNMENT)

Even if the fabric pattern is slanted in framing, it can be corrected from the operation panel, with no need for repeated attempts to re-frame.

Offer Personalised Embroidery Through E-Commerce and Stores

Tajima Software provides comprehensive support for embroidery personalisation, from receiving in-store or online e-commerce orders to production and management. It saves labour and increases efficiency while helping enhance brand loyalty and advertising effectiveness.

EASILY NETWORK YOUR SOFTWARE AND MACHINES FOR IMPROVED WORKFLOW.

All new machines come complete with a 2 year warranty, installation and operator training tailored to your needs.

Please contact our sales department for further information

on 01159 459 460

or email: sales@ajsemb.uk